AXIS#.SM.MODE

Description

AXIS#.SM.MODE defines the mode of service motion for each loop. Two types of service motion are available:

- A constant motion in one direction (endless or for a certain amount of time).

- An alternating motion.

The service motion can be stopped by using AXIS#.STOP .

The possible modes for this parameter are described in the following table:

|

AXIS#.SM.MODE |

Description |

Requirements |

|---|---|---|

|

0 |

Continuous or pulse motion using V1, I1 and T1

|

AXIS#.OPMODE = 0,1, or 2 AXIS#.CMDSOURCE = 0 |

|

1 |

Reversing motion

|

AXIS#.OPMODE = 0, 1, or 2 AXIS#.CMDSOURCE = 0

|

| 2 |

Continuous or pulse motion using V2, I2 and T2. However, the motion is described by AXIS#.SM.I2, AXIS#.SM.T2 and AXIS#.SM.V2. This enables a change on the fly and is mostly used under fieldbus control. |

AXIS#.OPMODE = 0, 1, or 2 AXIS#.CMDSOURCE = 0 |

Profiles

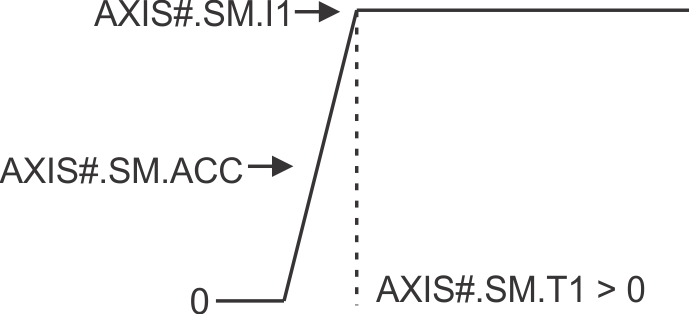

Service Motion for AXIS#.SM.MODE 0 and AXIS#.OPMODE 0 (Current)

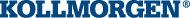

Profile when AXIS#.SM.T1 is greater than 0:

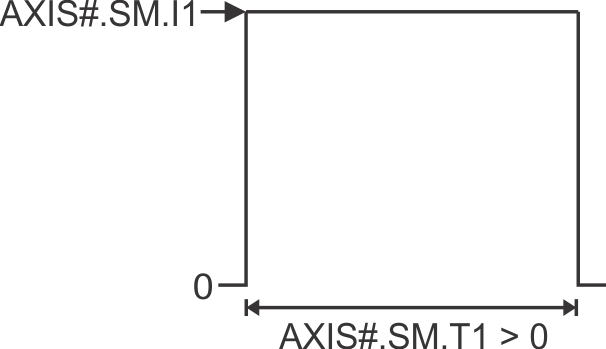

Profile when AXIS#.SM.T1 equals 0:

Service Motion for AXIS#.SM.MODE 0 and AXIS#.OPMODE 1 or 2 (Velocity or Position)

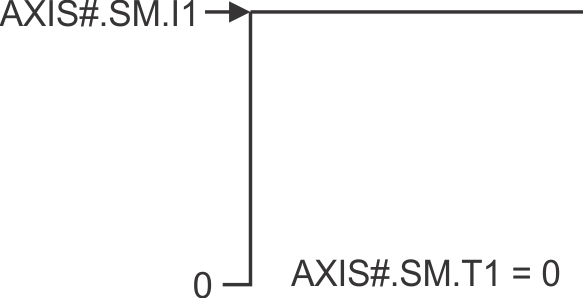

Profile when AXIS#.SM.T1 is greater than 0:

Profile when AXIS#.SM.T1 equals 0:

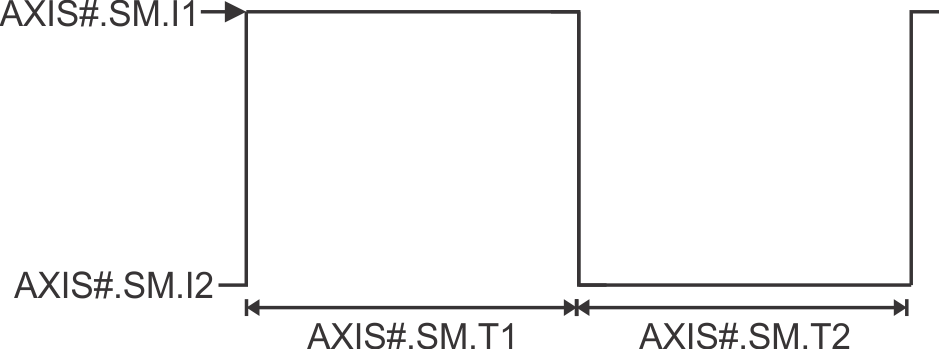

Service Motion for AXIS#.SM.MODE 1 and AXIS#.OPMODE 0 (Current)

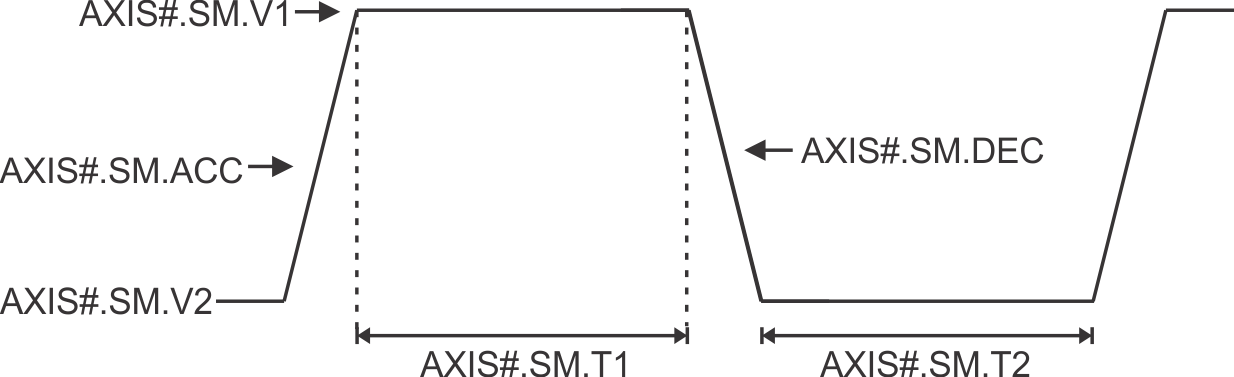

Service Motion for AXIS#.SM.MODE 1 and AXIS#.OPMODE 1 or 2 (Velocity or Position)

Versions

| Action | Version | Notes |

|---|---|---|

| Implemented | 02-00-00-000 |

General Information

|

Type |

Read/Write |

|

Units |

N/A |

|

Range |

0 to 2 |

|

Default Value |

0 |

|

Data Type |

Integer |

|

See Also |

|

|

Stored in Non Volatile Memory |

Yes |

Variants Supported

All variants are supported

Fieldbus Information

| Fieldbus |

Parameter | Index | Sub-Index | Data Type | Float Scale | Units | Access | PDO |

|---|---|---|---|---|---|---|---|---|

| EtherCAT |

AXIS1.SM.MODE | 0x500E | 0x3 | UINT | - | - | RW | False |

| AXIS2.SM.MODE | 0x510E | 0x3 | UINT | - | - | RW | False |